Focus on R&D and manufacturing of reducer for more than ten years

The function is to control the speed of mechanical transmission, which is widely used in the field of industrial machinery.

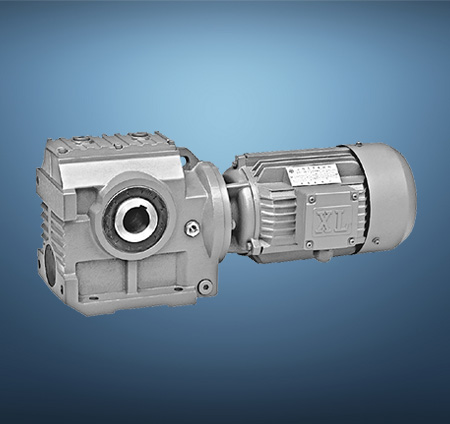

The S series reducer has a high technological content. It has a helical gear and a worm gear combined with an integrated transmission, which improves the torque and efficiency of the machine, and has a safe and reliable performance and a long life. It has implemented the requirements of international standards.

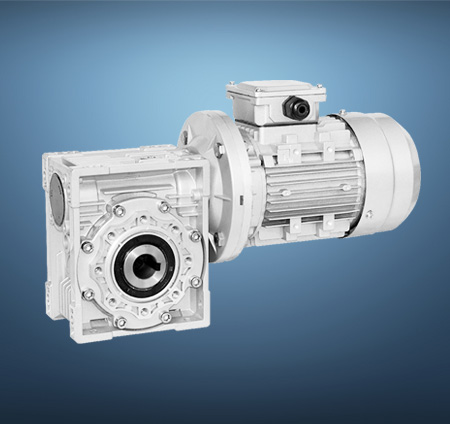

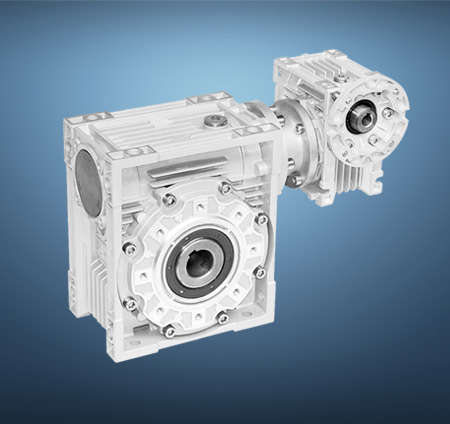

The RV series worm gear reducer is designed and manufactured according to the Q/MD1-2000 technical quality standard.Unique and novel "square box" outer structure, the box body is beautiful in appearance, and it is made of high-quality aluminum alloy die-casting.

NMRV series worm gear reducers are used in food, leather, textile, glass, ceramics, medical, chemical, light industry and other machinery and equipment industries, and are especially suitable for various automatic line transmission reducers.

Novel deceleration transmission device, can be connected and a variety of installation position selection according to user requirements.

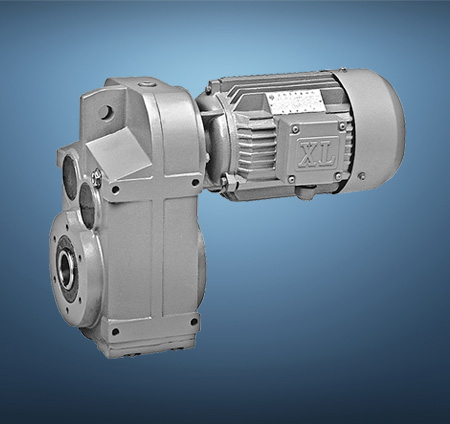

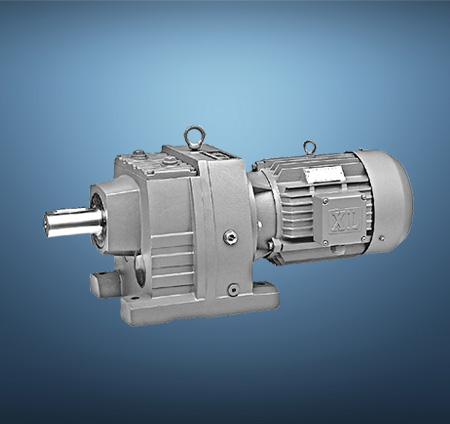

The F series parallel shaft helical gear reducer is manufactured in accordance with international technical requirements. It has a high technological content, saves space, is reliable and durable, has a high overload capacity, and the power can be more than 90KW.

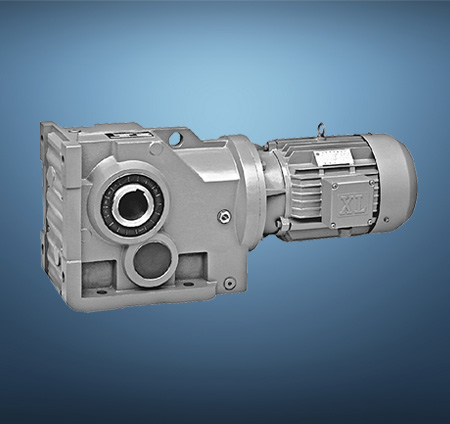

K series spiral bevel gear reducer is a combination of multi-stage helical gears, which has higher efficiency than single-stage worm gear reducers. It has high double torque efficiency and long-life gears. It is equipped with foot, flange and shaft installation.

R series helical gear reducer adopts high-quality steel cast iron box body, the hardness and impact performance of the box body are greatly improved, adopting the serialization and modular design idea, the transmission ratio is finely graded, and the transmission efficiency is high...

It is widely used in food machinery, printing, papermaking machinery, rubber, plastic machinery, ceramic machinery, pharmaceutical machinery and other fields.

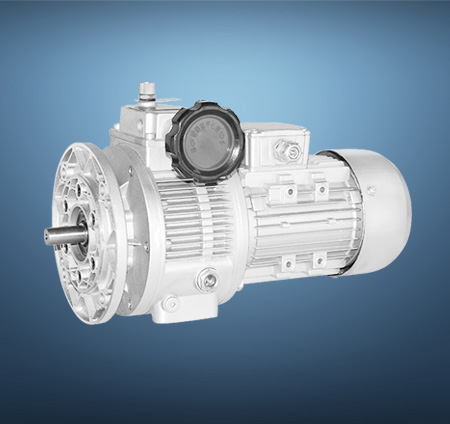

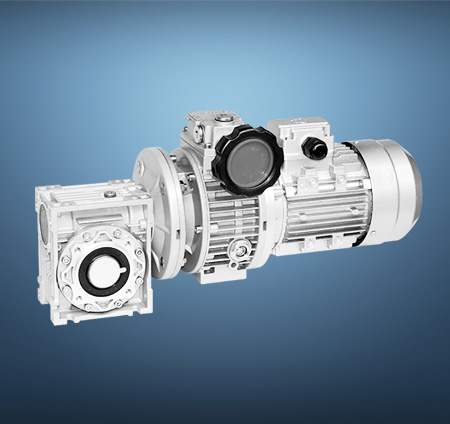

MB planetary friction type stepless speed machine is mainly composed of compact driving wheel device, friction transmission mechanism, and speed control mechanism.It is a widely used speed changer at present.

1. Better all-aluminum alloy die-casting shell

2、无级速度机输出速比1:1.4到1:7之间

3. Good applicability, can easily realize the motor + MB stepless speed changer + RV worm

Focus on reducer-more than 10 years of focus on the development and manufacturing of reducer

Have excellent equipment, solid technical modern management

Professional R&D team-design perfect reducer products for you

Perfect after-sales team, to provide you with timely and thoughtful after-sales service

A strategic partner worthy of your trust

Product performance is stable and reliable, hundreds of specifications products meet different needs

Passed ISO9001 international quality system certification

Based on perfect quality system and strict management

ABOUT US

Ever-Power Transmission Machinery Co., Ltd. (hereinafter referred to as Ever-Power Company) is a professional company engaged in R&D, manufacturing and sales of various types of worm gear reducers, continuously variable transmissions, and gear reducers.

Ever-Power mainly produces NMRV series worm gear reducer, MB series stepless speed changer, VF series worm gear reducer, X, WB series cycloidal pinwheel reducer, F, K, R, S series gear reducer, There are more than ten series and hundreds of specifications of reducer products such as T series spiral bevel gear steering gears and gear reversing boxes.

Ever-Power now has excellent production equipment, solid technical force, high-precision testing methods, and modern enterprise management level, which provide a reliable guarantee for product quality.

NEWS CENTER

Copyright © 2016 Ever-Power Transmission Machinery Co., Ltd. All Rights Reserved.