How to install and use worm gear reducer

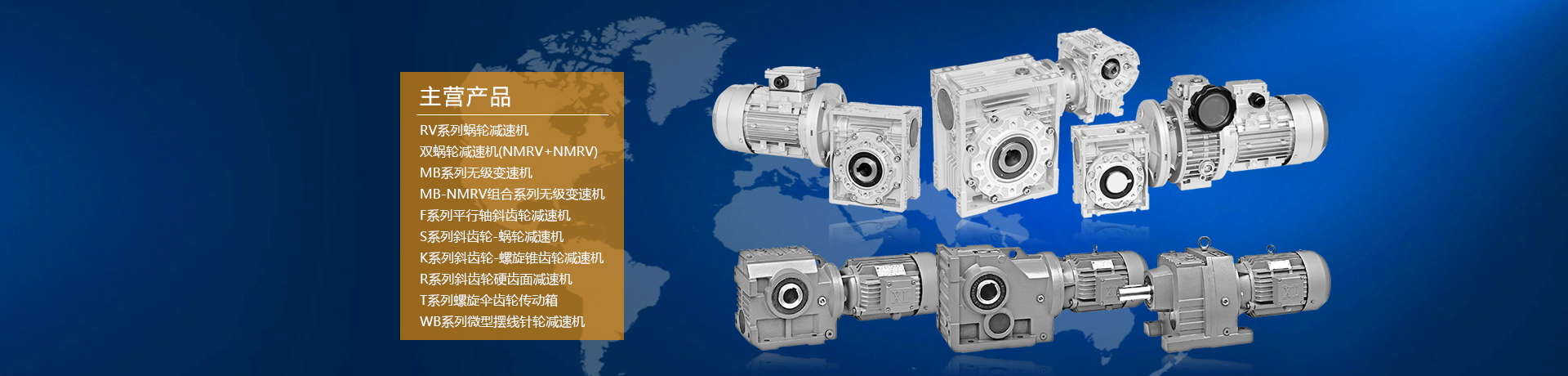

How to install and use the worm gear reducer. The input form of the reducer is divided into: hole input, shaft input, and extended worm shaft type; the output form of the reducer is divided into: hole output, one-way shaft output, and two-way shaft output.

Installation and use method of worm gear reducer

XNUMX. Basic performance

1. The worm speed is less than or equal to 1400rpm.

2、中心距有25、30、40、50、63、75、90、110、130共9种;

3、单机速比有7.5、10、15、20、25、30、40、50、60、80、100共11种速比;

4. The reducer can run in forward and reverse directions.

Second, the installation

1. A variety of installation methods can be used according to actual requirements, and all six sides can be installed;

2. The installation must be firm and reliable;

3. The working mechanism of the prime mover and reducer must be carefully aligned, and the error shall not be greater than the allowable compensation of the coupling used;

4. Rotate by hand after installation, it must be flexible and free from jamming.

Third, the use and replacement of lubricating oil

1. When using or replacing the worm gear reducer for the first time, replace the lubricating oil after running for 150-400 hours, and the subsequent oil change interval is less than or equal to 4000 hours;

2. Regularly check the quantity and quality of the oil, keep enough lubricating oil, and replace the oil mixed with impurities or deteriorated in time;

3. The amount of oil injection must be in accordance with the requirements of the table. The mixing of oils of different brands is prohibited, and the oils of the same brand but different viscosity are allowed to be mixed;

4. Attached table XNUMX for the amount of oil, and oil products according to the attached table XNUMX;

5、减速机工作环境温度为—40°C~+40°C,当环境温度低于0°C时,起动前润滑必须加热到0°C以上或采用低凝固点的润滑油。

Four, matters needing attention

1. Do not hammer the housing of the reducer with gravity to avoid damage;

2. Regularly check whether the installation foundation, seals, drive shaft, etc. are normal;

3. In normal use, the high temperature of the lubricating oil should be less than 85°C.When the oil temperature rises abnormally, and abnormal noise is generated, it should be shut down immediately for inspection. After the fault is excluded, the main can continue to use;

4. New spare parts must be used after running-in and load test.

Previous:Worm gear reducer is very annoying, how to reduce it?

Next:Matters needing attention in the use of worm gear reducer

Article Source:

Back to list- Precautions and characteristics of VF miniature worm gear reducer application

- Video display and characteristics of RV150 worm gear reducer

- How many combinations of worm gear reducers

- See the quality of NMRV worm gear reducer

- MB planetary cone-disk stepless speed changer and NMRV worm gear reducer unit set

- Installation position and flange position diagram of double worm gear reducer

- NMRV+NMRV double worm gear reducer characteristics and installation dimension table

- NMRV+NMRV double worm gear reducer marking and size table

- RV series worm gear reducer installation size and additional installation size table

- Technical parameters of RV series worm gear reducer